By Jimmy Chiu, Ph.D., Co-Founder and Chief Technology Officer at Loop CO2

Introduction: Why Debonding-on-Demand Matters Now

From electronics to automotive components, and from footwear to packaging, adhesive bonding has been the silent enabler of modern manufacturing. Yet in the era of circular economy and sustainable design, the permanence of adhesives has become both a strength and a challenge. A bonded product is often more durable, but when the time comes to repair, refurbish, or recycle, those same strong bonds can become barriers to material recovery.

Debonding-on-Demand (DoD) adhesives offer a different paradigm: strong and reliable during use, but capable of clean separation when activated by a specific trigger. This concept has moved from niche R&D projects into serious consideration by industries pressured by right-to-repair regulations, modular design trends, and corporate ESG commitments.

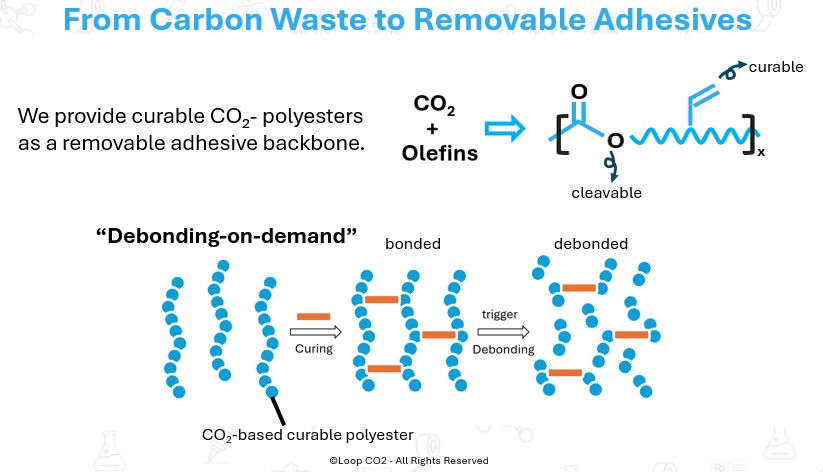

While DoD adhesives encompass a wide range of activation mechanisms, one recurring challenge across industries is identifying base chemistries that can adapt to multiple triggers without sacrificing performance. At Loop CO2, our CO₂-based unsaturated liquid polyesters with tunable reactive sites have demonstrated the ability to integrate seamlessly into thermal, photonic, and chemical systems, providing a versatile backbone that supports diverse debonding strategies within a single material platform.

This article provides a consolidated overview of the current design approaches in the DoD adhesives space, drawing from industry implementations, patent landscapes, and academic research directions. The goal is to create a practical toolbox of existing and emerging strategies to guide engineers, designers, and sustainability officers toward the right solutions for their specific needs.

The Industry’s Current Design Approaches

Debonding-on-Demand (DoD) adhesives have developed into a versatile toolbox of chemistries and activation mechanisms, each engineered to meet specific application needs, performance criteria, and end-of-life requirements. In commercial practice, these technologies are most often categorized by their activation stimulus—thermal, photonic, electrical, chemical, magnetic, or mechanical—with many formulations combining multiple triggers to enhance reliability and broaden applicability. This overview draws on peer-reviewed literature, most notably “Debondable adhesives and their use in recycling” by Bennett, C. R. and O’Reilly, R. K., Green Chem., along with publicly available corporate disclosures and an aggregated analysis of patents from leading developers such as Henkel, H.B. Fuller, and Tesa. Patent information was synthesized to identify common mechanisms and trends rather than cited individually, providing a concise summary of current DoD adhesive design strategies and technology development.

Table 1 below maps the current spectrum of DoD activation mechanisms, their underlying principles, representative industrial examples, and how Loop CO₂’s CO₂-based unsaturated liquid polyesters fit into each category. This serves as a quick reference before diving into the detailed discussion of each approach.

| Trigger Type | Core Mechanism | Typical Activation | Loop CO₂ Material Fit & Advantages |

| Thermal | Crystalline domain melting, foaming/expansion agents, thermal softening | 80–150 °C (above service temp) | Tailorable activation temp; maintains service integrity; depolymerizable to monomers; cross-linking to provide structural strength |

| Light | Photocleavage chemistry, photothermal conversion, photoinduced cross-linking | UV (300–400 nm), laser/NIR (800–1064 nm) | Unsaturated bonds in every monomer allow photoinduced over-crosslinking; adaptable to photothermal and photocleavage designs |

| Electrical | Joule heating via conductive fillers or meshes, electrochemical gas generation, charge separation with ionic additives | Low-voltage DC/AC (10–50 V), seconds–minutes | Compatible when blended with conductive fillers; extends multi-trigger capability |

| Electromagnetic Heating | Induction/RF heating via conductive or magnetic fillers | RF (kHz–MHz) or microwave (GHz) to reach 80–150 °C locally | Blendable with magnetic/conductive fillers; enables hybrid thermal activation |

| Chemical | Hydrolysis, solvent swelling, encapsulated chemical release | Specific pH, solvents, mild heat | Backbone allows targeted hydrolysis; controllable depolymerization for monomer recovery |

| Mechanical | Stress concentrators, vibration/ultrasound-assisted debonding | Directional pull or mechanical energy | Can be formulated into mechanically removable PSA systems for reusable designs |

1. Thermal-Triggered Systems

Principle:

Thermally activated DoD adhesives achieve debonding by inducing changes in the adhesive structure or its interfacial contact through polymer phase transitions, additive decomposition, or thermal expansion. Rather than chemically depolymerizing the adhesive, these systems typically employ physical or thermomechanical disruption to reduce bond strength.

Common strategies include:

- Crystalline domain melting: Incorporating high-melting-point crystalline polyols or polymer segments, commonly within polyurethane networks, that provide rigidity under normal service conditions. Upon heating, these crystalline domains lose their ordered structure, lowering cohesive strength and enabling clean peel-off without damaging substrates.

- Foaming and expansion agents: Embedding expandable microspheres or chemical blowing agents that swell when heated, generating internal stresses that disrupt the adhesive–substrate interface. In some designs, additives such as intumescent flame retardants decompose to release gases or form voids, aiding debonding while also enhancing fire resistance, an important feature for EV battery applications.

Industrial examples:

- H.B. Fuller EV Bond and EV Seal — Structural adhesives for battery modules that maintain strength during operation but soften at precisely controlled elevated temperatures for safe disassembly.

- Tesa thermally debondable tapes — Electronics assembly adhesives that release through expansion-triggered loss of interfacial contact.

Advantages:

Simple and well-established technology with straightforward integration into existing manufacturing; capable of uniform activation over large bonded areas; compatible with a wide range of adhesive chemistries and substrates.

Limitations:

Requires heating the entire bonded assembly, which can risk thermal damage to sensitive components; slower activation compared to localized methods; activation temperature must be set above service temperature to avoid premature debonding.

2. Light-Triggered Systems

Principle:

Light-activated DoD adhesives utilize optical energy to trigger debonding through direct chemical bond cleavage, localized heating, or structural transformation within the adhesive layer. These methods offer precise spatial control, enabling targeted disassembly without subjecting the entire bonded structure to high temperatures or chemical agents.

Common strategies include:

- Photocleavage chemistry: Incorporating light-labile linkages, such as o-nitrobenzyl groups or anthracene dimers, into the polymer backbone or side chains. Upon exposure to UV or visible light, these bonds undergo cleavage reactions, reducing the polymer’s molecular weight and sharply lowering adhesive strength.

- Photothermal conversion: Dispersing light-absorbing pigments or nanomaterials (e.g., carbon black, titanium dioxide, metal oxides) into the adhesive matrix or a dedicated interlayer. When irradiated with a specific wavelength, the absorbed energy is converted into heat, triggering localized thermal expansion, interface weakening, or partial decomposition.

- Photoinduced cross-linking: Using photoinitiators or photosensitive moieties to trigger over-crosslinking within the adhesive backbone upon exposure to high-energy light. The resulting excessive network density alters the mechanical properties, creating brittleness or interfacial stress that promotes adhesive failure. This method has been implemented in semiconductor dicing processes, where precision and minimal thermal load are critical.

Industrial examples:

- Tesa laser-assisted release adhesives — Designed for precision debonding via localized heating or ablation, widely used in electronics and optical assembly.

- Photocleavable adhesives in semiconductor packaging — Allow clean wafer separation while preserving delicate structures.

Typical activation range:

Dependent on the photochemistry and absorber type; activation wavelengths typically range from UV (300–400 nm) to near-IR/laser (800–1064 nm), with energy densities tuned to balance effective activation and substrate safety.

Advantages:

High precision, localized activation without heating the entire assembly.

Limitations:

Light penetration issues with opaque substrates; potential unintended activation by ambient light.

3. Electrically-Triggered Systems

Principle:

Electric-field activation induces debonding via Joule heating, electrochemical reactions, or electromechanical effects.

Common strategies include:

- Joule heating: Embedding conductive fillers (carbon nanotubes, graphite, metal particles) or conductive meshes into the adhesive. When voltage is applied, resistive heating softens the adhesive or activates embedded thermal agents.

- Electrochemical gas generation: Incorporating electroactive species that decompose under applied current to release gas, creating interfacial lift (still mostly experimental).

- Charge separation: Using inorganic or organic salt additives, often as ionic liquids, that migrate under low-voltage application (10–50 V) to the adhesive–substrate interface. This alters interfacial interactions and enables debonding, particularly when one or both substrates are conductive.

Industrial examples:

- Apple’s electrically releasable battery adhesive strips (reportedly supplied by Tesa), 9–12 V for 60 s triggers debonding.

- Henkel’s EV adhesives under development with low-current triggers integrated into the bond line.

- EIC Laboratories’ ElectRelease™ amine-cured epoxy systems, available in various adhesive strengths.

Advantages:

Remote, on-demand, and selective activation.

Challenges:

Uniform heating in large structures; safety concerns in high-energy systems like EV batteries.

4. Chemically-Triggered Systems

Principle:

Chemical activation uses solvents, pH change, or reactive agents to weaken adhesive cohesion or adhesion.

Common strategies include:

- Hydrolysable adhesives: Incorporating labile linkages (esters, acetals) that degrade in specific conditions.

- Encapsulated agents: Microcapsules containing solvents or plasticizers dispersed in the adhesive matrix, which release upon external stimulus (pressure, heat) to soften the adhesive locally.

Industrial examples:

- Henkel’s Loctite 3382 through debonding by warm water.

- HB Fuller’s Alkali-soluble PSAs for easy label removal.

- Research-stage microcapsule systems using esters (e.g., hexyl acetate) to trigger modulus reduction upon capsule rupture.

Advantages:

High selectivity; potential for environmentally friendly triggers.

Limitations:

Chemical compatibility with substrates; slower activation compared to physical triggers; challenging accessibility to chemical stimulus.

5. Electromagnetic Heating–Triggered Systems

Principle:

Electromagnetic heating in DoD adhesives relies on induction heating or radio-frequency (RF) energy to generate heat directly within the bond line. This is achieved by incorporating magnetic or conductive materials, such as metal particles, metal-coated fibers, or ferrite fillers, into the adhesive formulation or an embedded interlayer. When exposed to an alternating electromagnetic field, these additives dissipate energy as heat through eddy current losses (conductive fillers) or hysteresis losses (magnetic fillers), rapidly raising the local temperature and triggering a thermal debonding mechanism.

Common strategies include:

- Induction heating layers: Placing a conductive or magnetic layer beneath or within the adhesive layer, which heats rapidly under an AC electromagnetic field. This heat softens thermoplastic phases, activates foaming agents, or initiates reversible bond cleavage.

- Magnetic particle-loaded adhesives: Directly dispersing ferromagnetic or ferrimagnetic fillers (e.g., iron oxide, ferrite powders) in the adhesive to enable uniform heating across the joint under RF or microwave exposure.

- Hybrid systems: Combining electromagnetic heating with other triggers (e.g., chemical blowing agents or reversible covalent bonds) to enhance debonding efficiency and reduce the required energy input.

Industrial examples:

- H.B. Fuller RF-induction debonding adhesives — Structural adhesives with embedded ferromagnetic particles for EV battery pack disassembly, enabling selective heating of the bond line without affecting the entire module.

- Henkel induction-responsive structural adhesives — Designed for maintenance and repair of large components, using metal-coated glass fibers to focus heating at the interface.

Typical activation range:

Localized temperatures are tuned to match the thermal trigger of the adhesive matrix (generally 80–150 °C), with heating achieved in seconds to minutes depending on coil design and field strength. The external electromagnetic frequency typically falls in the RF (kHz–MHz) range for induction or GHz range for microwave systems.

Advantages:

Rapid, localized heating without raising the temperature of the entire assembly; non-contact activation suitable for sealed or hard-to-reach joints; scalable to large structures like EV battery packs; compatible with other thermal debonding methods.

Limitations:

Requires conductive or magnetic elements in the adhesive or substrate; added equipment cost and setup complexity; limited penetration in thick or shielded structures; safety considerations near sensitive electronics.

6. Mechanically-Triggered Systems

Principle:

Mechanical debonding designs use structural engineering to facilitate clean removal when specific forces are applied.

Common strategies include:

- Stress concentration design: Adhesives or tapes engineered with microstructured layers that collapse under directional pull, breaking adhesion.

- Vibration/ultrasound-assisted: Applying high-frequency mechanical energy to weaken adhesive bonds, used mainly in lab-scale or niche industrial disassembly.

Industrial examples:

- 3M Command™ strips — Consumer adhesive hooks and strips designed for clean removal via directional pulling.

- TESA Bond & Detach — Industrial tapes with engineered layers enabling low-residue removal for electronics and display applications.

Advantages:

No heat or chemicals required; immediate removal.

Limitations:

May require access to the bond line and manual operation; less suited to high-strength structural bonds without prior weakening.

Mapping the Toolbox: Selecting the Right DoD Approach

The DoD landscape encompasses a spectrum of well-established and emerging mechanisms, from crystalline-domain melting and photothermal conversion to induction-heating hybrids and charge-separation chemistries. No single approach fits all applications, and selection must be guided by the technical match between activation method and product requirements. For engineers and product designers, key decision factors include:

• Trigger compatibility with the product’s defined end-of-life process, whether it involves thermal, optical, electrical, or chemical activation.

• Substrate sensitivity to heat, light, or chemicals, which may exclude certain trigger types.

• Manufacturing integration into current assembly lines without significant retooling, especially for high-throughput sectors like electronics and automotive.

• Regulatory and sustainability compliance, including VOC limits, REACH restrictions, and circular economy targets.

By treating DoD options as a modular technology toolbox—with triggers, chemistries, and performance parameters that can be configured—companies can assemble solutions optimized for their specific market and process constraints. In this context, Loop CO₂’s CO₂-based unsaturated liquid polyesters offer a single base chemistry that can integrate into multiple trigger systems without compromising performance, giving designers a flexible platform for meeting both technical and sustainability requirements.

A Material That Fits Multiple Designs: Our Contribution to the Toolbox

Within this evolving landscape, Loop CO₂’s unsaturated liquid polyesters with tunable reactive sites stand out for their adaptability. Their liquid-state processability allows direct blending into diverse adhesive formulations without altering existing manufacturing lines. The unsaturated bonds in the polymer backbone enable:

• Thermal, photochemical, or chemical crosslinking for tailored performance.

• Reversible bonding through dynamic covalent linkages, allowing targeted debonding and potential adhesive recovery.

• Post-functionalization for specific substrate interactions or trigger sensitivities.

When synthesized from CO₂-derived monomers, these materials also deliver a measurable carbon footprint advantage. Rather than competing with existing DoD designs, they act as a multi-functional insert—compatible with heat-, light-, and chemically triggered systems—broadening the applicability of current adhesive toolkits.

Conclusion: Building the Future of Reversible Bonding

Debonding-on-Demand adhesives have progressed from niche solutions to strategic enablers of product circularity. With tightening regulations, growing emphasis on design-for-disassembly, and the cross-pollination of innovations between sectors, adoption is no longer a question of if but which technology pathway will prevail. Solutions like Loop CO₂’s polyesters, which bridge multiple trigger mechanisms, maintain high in-service performance, and enable full monomer recovery, illustrate how molecular-level design can deliver both functional and sustainability wins. For decision-makers, this means evaluating not just the bond, but the entire bonding strategy as part of a product’s lifecycle.